I-TCT Hole Saw yeNsimbi eNgatyiwayo, i-aluminiyam, ubhedu njl

Iimbonakalo

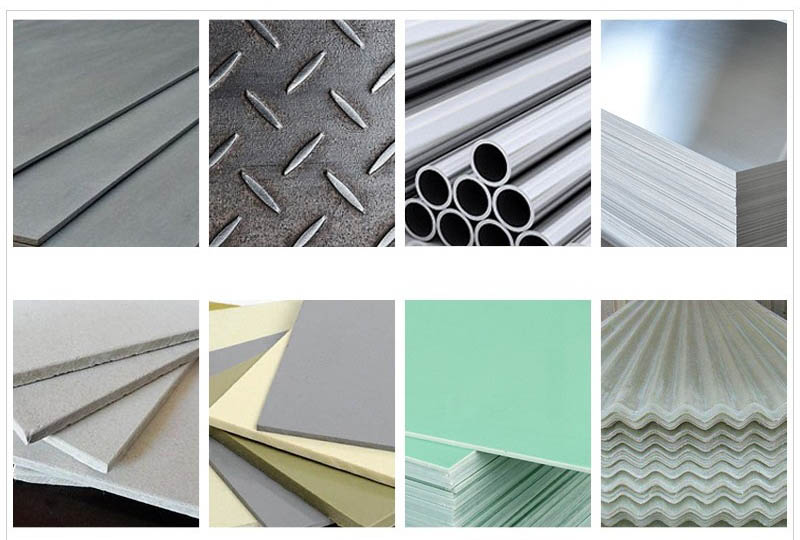

1. Iisarha ze-TCT zomngxuma zixhotyiswe ngamazinyo e-tungsten carbide, abukhali ngokugqithiseleyo kwaye ahlala ixesha elide. Oku kuvumela ukusika ngokufanelekileyo ngokusebenzisa izinto ezomeleleyo njengentsimbi engatyiwa, ialuminium, ubhedu, nokunye.

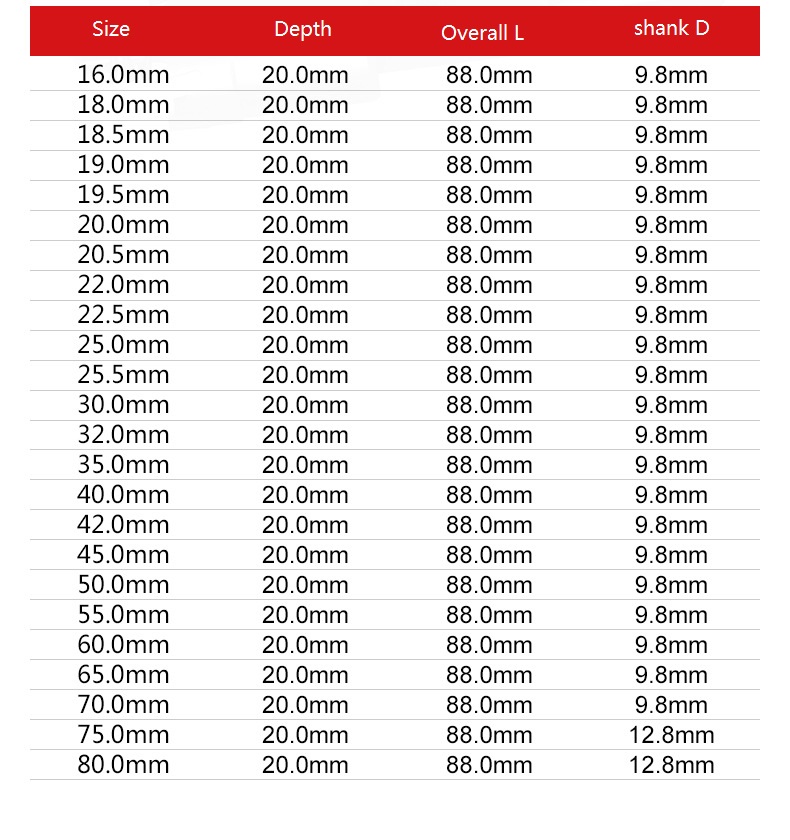

2. Iisarha zemingxunya ye-TCT ziza ngobukhulu obahlukeneyo ukuze zibambe iidayamitha zomngxuma ezahlukeneyo. Oku kubonelela ngeendlela ezahlukeneyo kunye nokuguquguquka ekusikeni imingxuma yobungakanani obuhlukeneyo kwizinto ezahlukeneyo.

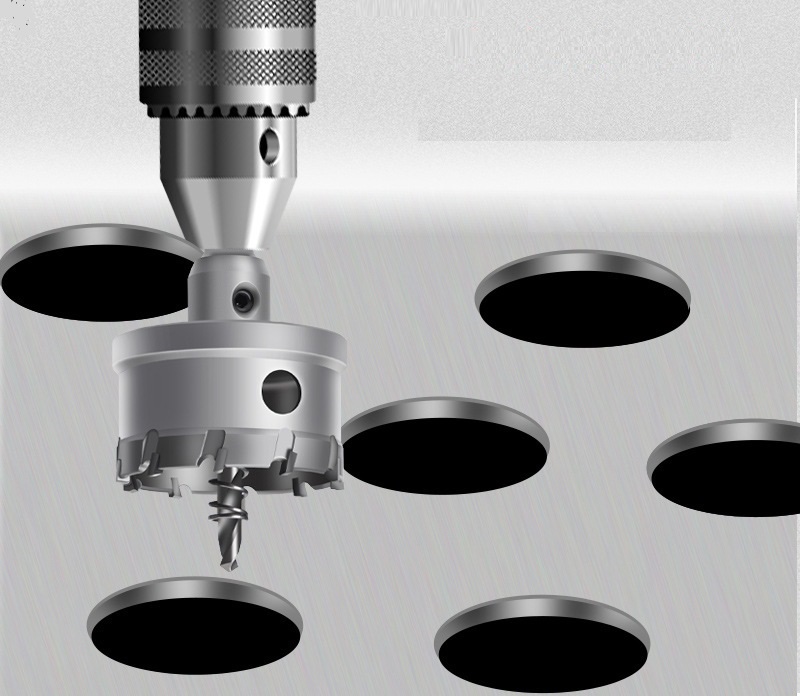

3. I-TCT i-saws ye-hole yenzelwe ukusika i-high-speed cut, ivumela ukukhawuleza kunye nokusebenza ngokufanelekileyo. Oku konga ixesha kwaye kwandisa imveliso.

4. Ubukhali bamazinyo e-tungsten carbide buqinisekisa ukusika okucocekileyo kunye nokuchanekileyo kwinsimbi engenasici, i-aluminium, ubhedu kunye nezinye izinto. Oku kunciphisa imfuno yomsebenzi owongezelelweyo wokugqiba kwaye iqinisekisa umphumo okhangelekayo.

5. Iisarha ze-TCT zemingxuma zakhiwe ukuze zimelane nobunzima bokusika izinto ezinzima. Zinolwakhiwo olomeleleyo olwandisa ukuqina kunye nokuphila ixesha elide, naphantsi kokusetyenziswa kakhulu.

6. Uyilo lweesarha ze-TCT zomngxuma zibandakanya iiflethi ezikhethekileyo okanye iindawo zokubeka ezincedisa ukukhutshwa kwe-chip ngexesha lokusika. Oku kunceda ukuthintela ukuvala kunye nokushisa, ukuvumela ukusika okuqhubekayo ngaphandle kokuphazamiseka.

7. Iisarha ze-TCT zemingxuma zenzelwe ukuba zihambelane noomatshini abaqhelekileyo bokugaya okanye i-arbors. Zinokudityaniswa ngokulula kwaye ziqhawuke, zizenze zibe lula kwaye zisebenziseke lula.

8. Amazinyo e-tungsten carbide aneempawu ezintle zokumelana nobushushu. Oku kuvumela ii-saws ze-TCT zomngxuma ukuba zigcine ukusebenza kwazo kokusika nokuba kubushushu obuphezulu obuveliswe ngexesha lokomba.

9. Iisarha ze-TCT zomngxuma zingasetyenziselwa uluhlu olubanzi lwezicelo, ezifana nemibhobho, umsebenzi wombane, ukufakwa kwe-HVAC, ukuveliswa kwesinyithi, kunye nokunye. Zikulungele ukusika imingxuma kwintsimbi engatyiwa, i-aluminium, ubhedu, kunye nezinye izinto eziqhelekileyo ezidibana nazo kula mashishini.

10. Iisarha ze-TCT zomngxuma zizixhobo zogcino oluphantsi. Emva kokusetyenziswa, kuyacetyiswa ukuba uhlambulule kwaye ususe nayiphi na inkunkuma okanye iichips. Oku kunceda ukwandisa ubomi babo kunye nokuqinisekisa ukusebenza kakuhle kokusika.

Iinkcukacha zeMveliso

umzi-mveliso