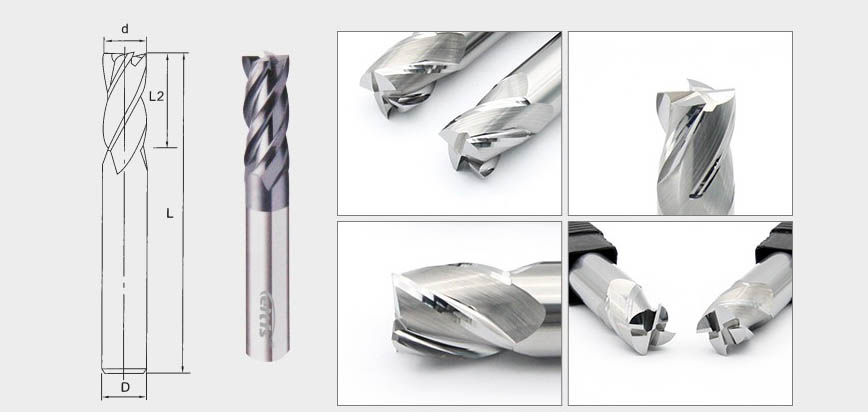

I-Solid Carbide Square End Mills yomatshini jikelele

Iimbonakalo

1. Izinto eziphathekayo: Izixhobo eziqinileyo ze-square ze-square ze-carbide zenziwe kwisiqwenga esisodwa se-carbide, esiqinisekisa ukuqina okuphezulu kunye nokuchasana nokugqoka kunye nokukrazula.

2. Ubunzima: I-Carbide iyaziwa ngobulukhuni bayo obukhethekileyo. Ii-square ze-square eziqinileyo ze-carbide ziyakwazi ukumelana nesantya esiphezulu sokusika kwaye zigcine ubukhali babo ixesha elide xa kuthelekiswa nezinye izinto.

3. Ukuchaneka: Ii-square ze-square ze-carbide eziqinileyo ziyilwe ngokuchaneka kwengqondo. Bayakwazi ukuvelisa ukusika okuchanekileyo kunye nokucocekileyo, okukhokelela kwizinto zokusebenza ezichanekileyo kunye neziphezulu.

4. I-Versatility: Ezi zixhobo zokugqibela zinokusetyenziswa kwizinto ezahlukeneyo, kubandakanywa isinyithi se-ferrous kunye ne-non-ferrous, iiplastiki kunye ne-composites. Oku kuguquguquka kubenza bafaneleke kuluhlu olubanzi lwezicelo zomatshini.

5. Ukusebenza kakuhle: I-solid carbide square end Mills ziyilwe ngeefluti ezininzi, eziphucula ukukhutshwa kwe-chip kunye nokunciphisa amathuba okuvala. Oku kuphucula ukusebenza kakuhle komatshini kunye nemveliso ngokubanzi.

6. Ukumelana nokushisa: I-Carbide ineempawu ezintle zokumelana nokushisa, ivumela i-carbide eqinile i-square end Mills ukumelana nobushushu obuphezulu obuveliswa ngexesha lokusika imisebenzi ngaphandle kokulahlekelwa ubunzima babo okanye ubukhali.

7. Ubomi obude: Ngenxa yobunzima obuphezulu kunye nokuqina, i-carbide eqinile i-square end mills inobomi obude xa kuthelekiswa nezinye iintlobo zokuphela. Oku kubangela ukutshintshwa kwezixhobo ezimbalwa, ukunciphisa ixesha lokunciphisa kunye neendleko.

8. Ukuqina okuphezulu: Izixhobo zokuphela kwe-carbide eziqinileyo zinokuqina okuphezulu, oku kuthetha ukuba akunakwenzeka ukugoba okanye ukuphambuka ngexesha lomsebenzi womatshini. Oku kuqina kukhokelela ekuphuculeni ukuzinza kokusika kunye nokuchaneka komda.

9. Iinketho zokugquma: Izixhobo eziqinileyo ze-square end Mills zinokuthi zigqunywe ngeengubo ezahlukeneyo ezifana ne-TiN, i-TiCN, kunye ne-TiAlN, eziphucula ngakumbi ukusebenza kwazo ngokunciphisa ukukhuhlana, ukwandisa ubomi besixhobo, kunye nokuphucula ukukhutshwa kwe-chip.

10. Ijiyometri ye-Cutting-edge: Ii-square end Mills ze-carbide ziyafumaneka kwiijometri ezahlukeneyo zokusika, ezifana noyilo oluthe tye, lwe-helical, kunye nolwahlukeneyo lwe-helix. Ezi geometri zibonelela ngeempawu zokusika ezahlukeneyo kwaye zijongana neemfuno ezithile zomatshini.

Umboniso weenkcukacha

FACTORY

Iingenelo

1. Ukuhlala ixesha elide: I-Solid carbide i-square end Mills zaziwa ngokuqina kwazo okukhethekileyo. Izinto zeCarbide zixhathisa ukunxiba kwaye ziyakwazi ukumelana nesantya esiphezulu sokusika kunye nezixhobo eziqhekezayo, ezikhokelela kubomi obude besixhobo.

2. I-Speed Speed Machining: Ii-square ze-square eziqinileyo ze-carbide ziyakwazi ukwenza ngokufanelekileyo imisebenzi ye-high-speed machining ngenxa yobunzima babo kunye nokumelana nobushushu. Oku kuvumela ukwanda kwemveliso kunye namaxesha amafutshane omatshini.

3. UkuPhuculwa kweChip okugqwesileyo: Iifluti ezikwi-square end Mills ze-carbide ziyilelwe ukwenza ngcono ukukhutshwa kwe-chip. Oku kunceda ukukhusela ukwakhiwa kwe-chip kunye nokuqinisekisa ukusika okugudileyo, ukunciphisa umngcipheko wokulimala kwesixhobo okanye iziphene zomsebenzi.

4. UkuPhuculwa koMphezulu oPhuculweyo: Ii-square ze-square ze-carbide eziqinileyo zivelisa ukusika okucocekileyo kunye nokuchanekileyo, okukhokelela ekugqityweni okuphezulu kwendawo yokusebenza. Oku kuphelisa imfuno yeenkqubo zokugqiba ezongezelelweyo, ukugcina ixesha kunye neendleko.

5. I-Versatility: Ii-square end Mills ze-carbide eziqinileyo zilungele uluhlu olubanzi lwezinto eziphathekayo, ezibandakanya isinyithi, iiplastiki, kunye neengqungquthela. Oku kuguquguquka kubenza balungele amashishini ahlukeneyo, ukusuka kwimoto ukuya kwi-aerospace.

6. Uzinzo oluphuculweyo: I-square end Mills ye-carbide eqinile ibonisa ukuqina okuphezulu, okunciphisa ukuchithwa kwesixhobo kunye nokwandisa ukuzinza kokusika. Oku kubangela ukuchaneka okuphuculweyo kunye nokunciphisa amathuba okuqhekeka kwesixhobo.

7. UkuCwangciswa koCwangciso: Imida ebukhali yokusika i-square ye-square end Mills ivumela umatshini ochanekileyo kunye nochanekileyo. Oku kubalulekile kwizicelo ezifuna unyamezelo olungqongqo kunye neenkcukacha ezintsonkothileyo.

8. Ukumelana nokushisa: Iinqwelo eziqinileyo ze-carbide ziyakwazi ukumelana nokushisa okuphezulu okwenziwe ngexesha lomatshini. Oku kuxhathisa ukushisa kuthintela isixhobo ukuba sithambe okanye siphulukane neempawu zokusika, ukuqinisekisa ukusebenza okuhambelanayo.

9. IiNguqulelo zeSixhobo eziNcitshisiweyo: Iinqwelo ze-square ze-carbide eziqinileyo zinexesha elide lesixhobo xa kuthelekiswa nezinye izinto, ukunciphisa isidingo sokutshintsha izixhobo rhoqo. Oku kukhokelela ekusebenzeni kakuhle kwemveliso kunye nokuncipha kwexesha lokunciphisa.

10. Iindleko-zokusebenza: Nangona ekuqaleni zibiza kakhulu, i-slid carbide square end Mills zibonelela ngogcino lweendleko zexesha elide ngenxa yobomi babo besixhobo esandisiweyo kunye nobuchule bokusebenza okuphezulu. Oku kubenza ukhetho olungabizi kakhulu kwimisebenzi yokuvelisa.

| Iblade idayamitha (mm) | Ubude beblade (mm) | Igcwele(mm) | I-Shank (mm) |

| 1.0 | 3 | 50 | 4 |

| 1.5 | 4 | 50 | 4 |

| 2.0 | 6 | 50 | 4 |

| 2.5 | 7 | 50 | 4 |

| 3.0 | 8 | 50 | 4 |

| 3.5 | 10 | 50 | 4 |

| 4.0 | 11 | 50 | 4 |

| 1.0 | 3 | 50 | 6 |

| 1.5 | 4 | 50 | 6 |

| 2.0 | 6 | 50 | 6 |

| 2.5 | 7 | 50 | 6 |

| 3.0 | 8 | 50 | 6 |

| 3.5 | 10 | 50 | 6 |

| 4.0 | 11 | 50 | 6 |

| 4.5 | 13 | 50 | 6 |

| 5.0 | 13 | 50 | 6 |

| 5.5 | 13 | 50 | 6 |

| 6.0 | 15 | 50 | 6 |

| 6.5 | 17 | 60 | 8 |

| 7.0 | 17 | 60 | 8 |

| 7.5 | 17 | 60 | 8 |

| 8.0 | 20 | 60 | 8 |

| 8.5 | 23 | 75 | 10 |

| 9.0 | 23 | 75 | 10 |

| 9.5 | 25 | 75 | 10 |

| 10.0 | 25 | 75 | 10 |

| 10.5 | 25 | 75 | 12 |

| 11.0 | 28 | 75 | 12 |

| 11.5 | 28 | 75 | 12 |

| 12.0 | 30 | 75 | 12 |

| 13.0 | 45 | 100 | 14 |

| 14.0 | 45 | 100 | 14 |

| 15.0 | 45 | 100 | 16 |

| 16.0 | 45 | 100 | 16 |

| 17.0 | 45 | 100 | 18 |

| 18.0 | 45 | 100 | 18 |

| 19.0 | 45 | 100 | 20 |

| 20.0 | 45 | 100 | 20 |

| 22.0 | 45 | 100 | 25 |

| 25.0 | 45 | 100 | 25 |