I-Solid Carbide Machine Reamer ene-Spiral Flute

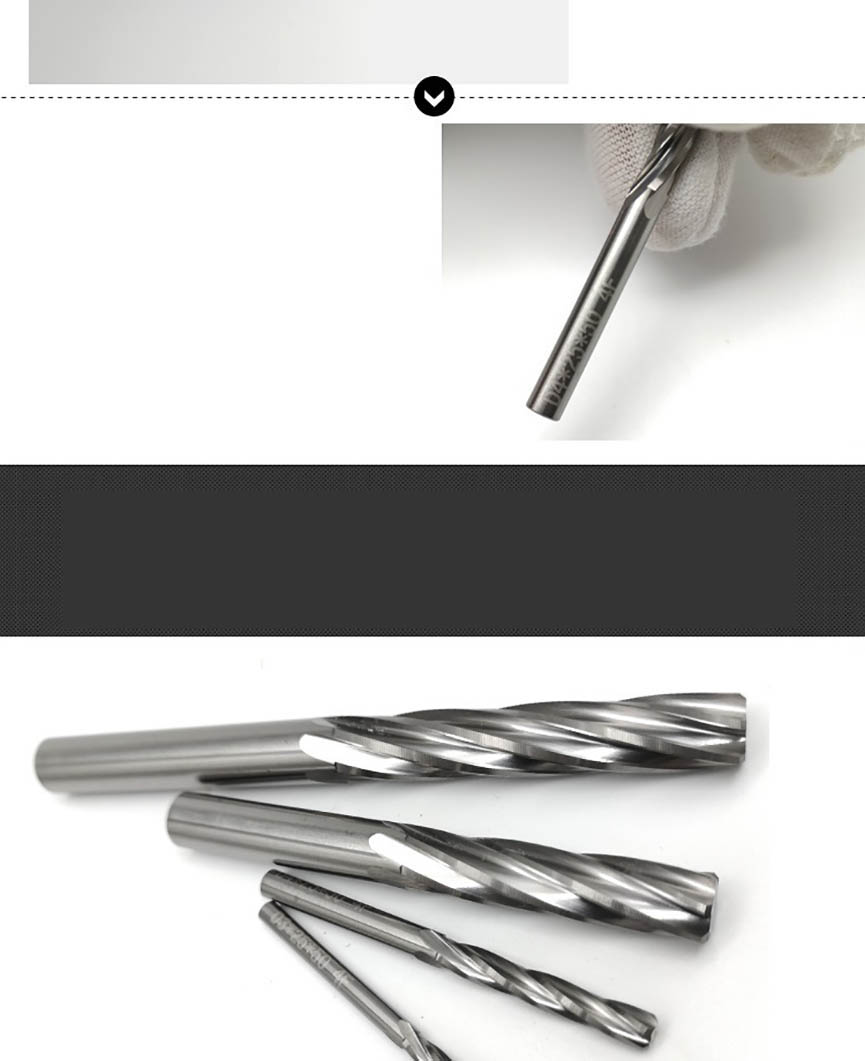

Iingenelo

1. Ubunzima obuphezulu kunye nokuNxitywa kwe-Resistance: I-carbide eqinile yinto enzima kakhulu kwaye ehlala ixesha elide enokumelana nesantya esiphezulu sokusika kwaye igcine umgca wayo wokusika ixesha elide. Obu bunzima kunye nokumelana nokunxiba kwenza ukuba ii-reamers ze-carbide zilungele ukusetyenziswa kwizicelo ezifunwayo kunye nemathiriyeli.

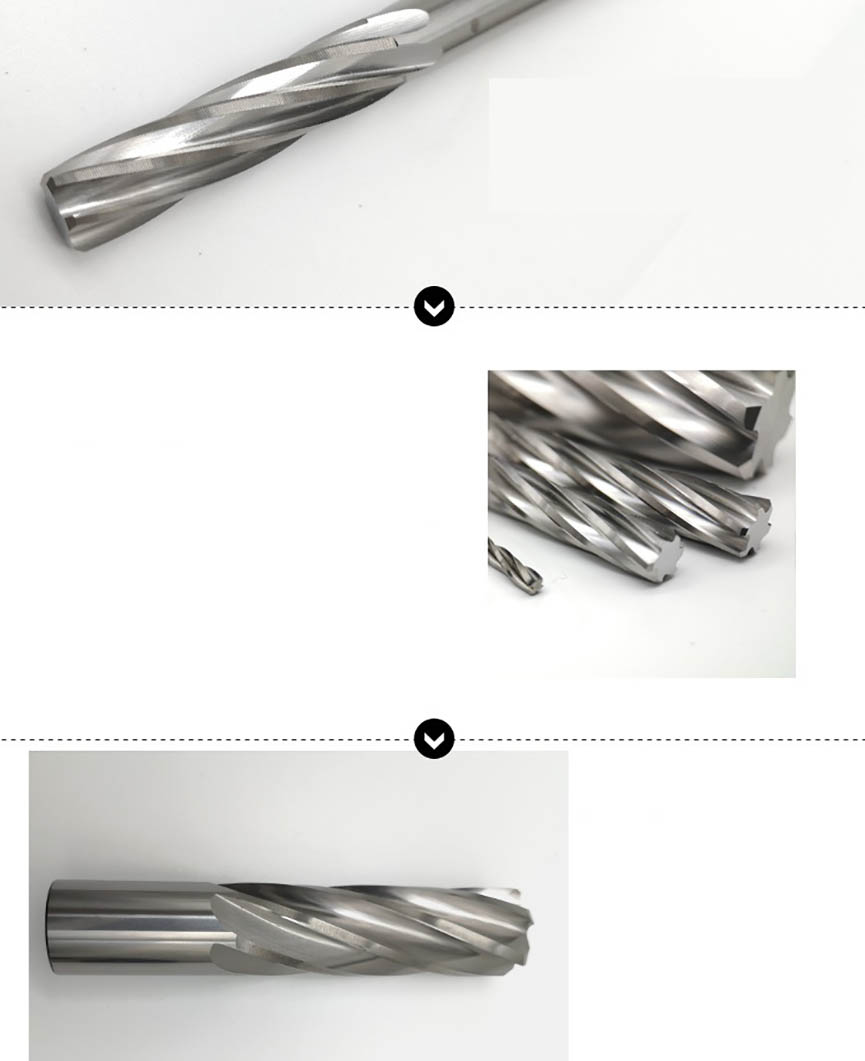

2. Ukukhutshwa kweChip okugqwesileyo: Uyilo lweflute ejikelezayo yomatshini oqinileyo we-carbide reamers ivumela ukukhutshwa okusebenzayo kwe-chip ngexesha lenkqubo yokubuyisela kwakhona. Iifluti ezijikelezayo zinceda ukunqanda ukuvaleka kwetshiphu okanye ukuxinana, ziphucula ukusebenza kwesixhobo sokuvuselela kunye nemveliso.

3. Ukunyuka kwezantya zokusika: Ngenxa yobunzima babo obuphezulu, izixhobo eziqinileyo zomatshini we-carbide zingasetyenziswa kwisantya esiphezulu sokusika kunezinye izinto ezisebenzayo. Oku kuvumela ukukhawuleza kunye nokusebenza ngokufanelekileyo kokuphinda kusebenze, ukunciphisa ixesha lomatshini kunye nokunyusa imveliso.

4. Ukugqitywa koMphezulu oMomeleziweyo: Izitshizi zomatshini we-carbide eziqinileyo ezinefluti ezijikelezayo zivelisa ukugqibezela komphezulu ogudileyo kumngxunya owenziwe ngoomatshini. Ukucwangciswa kweflute ejikelezayo kunceda ukunciphisa incoko kunye nokungcangcazela ngexesha lenkqubo yokusika, okukhokelela kumgangatho ophuculweyo womngxuma kunye nokuchaneka.

5. Ubomi beSixhobo eSide: Umatshini oqinileyo we-carbide unobomi obude besixhobo xa kuthelekiswa nezinye izinto zokuvuselela. Ukumelana nokunxiba okuphezulu kunye nokuqina kwabo kubavumela ukuba bamelane neemeko ezinzima eziqubisana nazo ngexesha lokuphinda ziphinde zifakwe, ukunciphisa ukuphindaphindeka kotshintsho lwesixhobo kunye nexesha lokuphumla elihambelanayo.

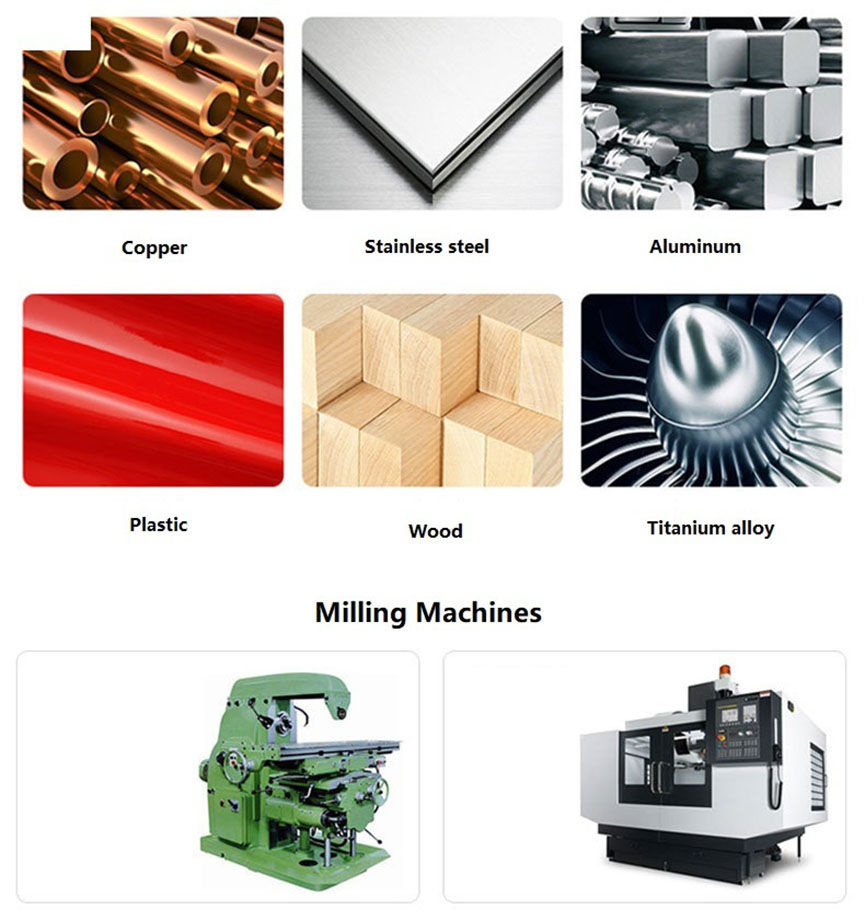

6. I-Versatility: Umatshini oqinileyo we-carbide reamers kunye ne-spiral flute ingasetyenziselwa kwizinto ezininzi, ezibandakanya iintsimbi, i-stainless steels, i-cast iron, kunye ne-non-ferrous metals. Banokusingatha zombini ukusikeka okuphazamisekileyo kunye nemisebenzi eqhubekayo yokubuyisela kwakhona kwizinto ezahlukeneyo zokusebenza.

7. Uzinzo oluthe kratya lwe-Reamer: Idizayini ye-spiral flute yezi reamers inceda ukuphucula uzinzo ngexesha lenkqubo yokusika. Oku kunciphisa ukuphambuka, kuthintela ukuncokola, kwaye kuqinisekisa ukudalwa komngxuma ochanekileyo ngakumbi.

8. Ukuchaneka kweDimensional: Umatshini oqinileyo we-carbide reamers wenziwa ukunyamezela okuqinileyo, ukubonelela ngokuchaneka okugqwesileyo kunye nokuhambelana. Oku kubenza bafanelekele izicelo ezifuna i-diameter echanekileyo yomngxuma kunye nokunyamezela okuqinileyo.

9. UkuNcitshiswa kweSixhobo soLondolozo: Ngenxa yobunzima babo obukhethekileyo kunye nokuxhatshazwa kokugqoka, izixhobo eziqinileyo zomatshini we-carbide zifuna ukulolwa okuncinci kunye nokugcinwa ngokuthelekiswa nezinye iintlobo ze-reamer. Oku kunciphisa ubungakanani bexesha kunye neenzame ezichithwe ekugcinweni kwesixhobo kwaye kuvumela umatshini ongaphazamiseki ngakumbi.

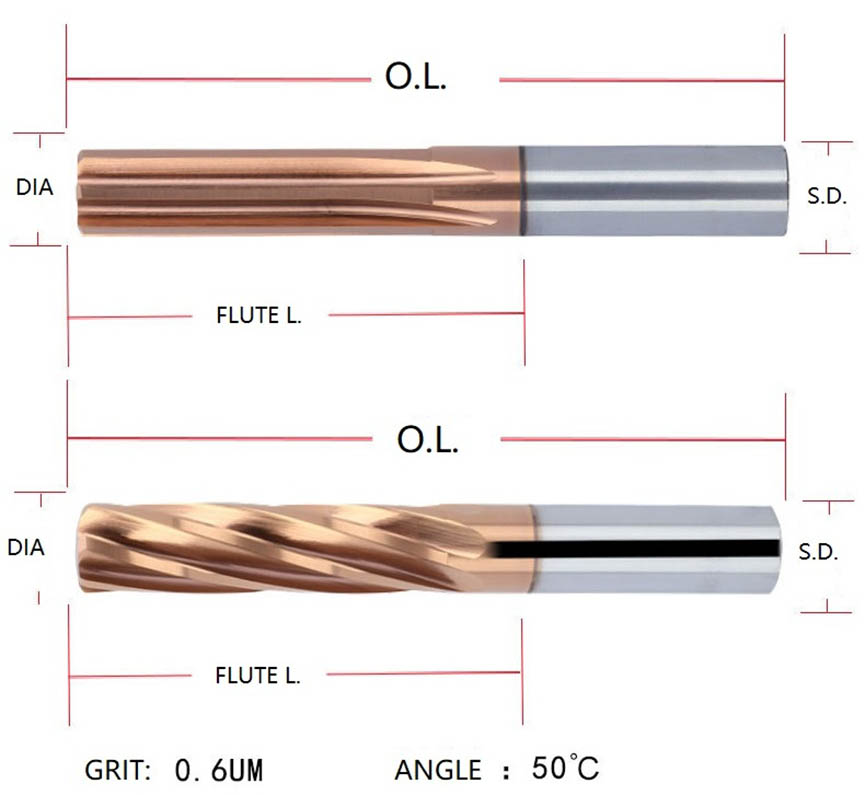

UMBONISO WEMVELISO

| I-DIA | UFLUTE L. | SHANK DIA | LONKE L. | IIFLUTES | |

| 3 | 30 | 3D | 60L | 4F | |

| 4 | 30 | 4D | 60L | 4F | |

| 5 | 30 | 5D | 60L | 6F | |

| 6 | 30 | 6D | 60L | 6F | |

| 8 | 40 | 8D | 75L | 6F | |

| 10 | 45 | 10D | 75L | 6F | |

| 12 | 45 | 12D | 75L | 6F | |