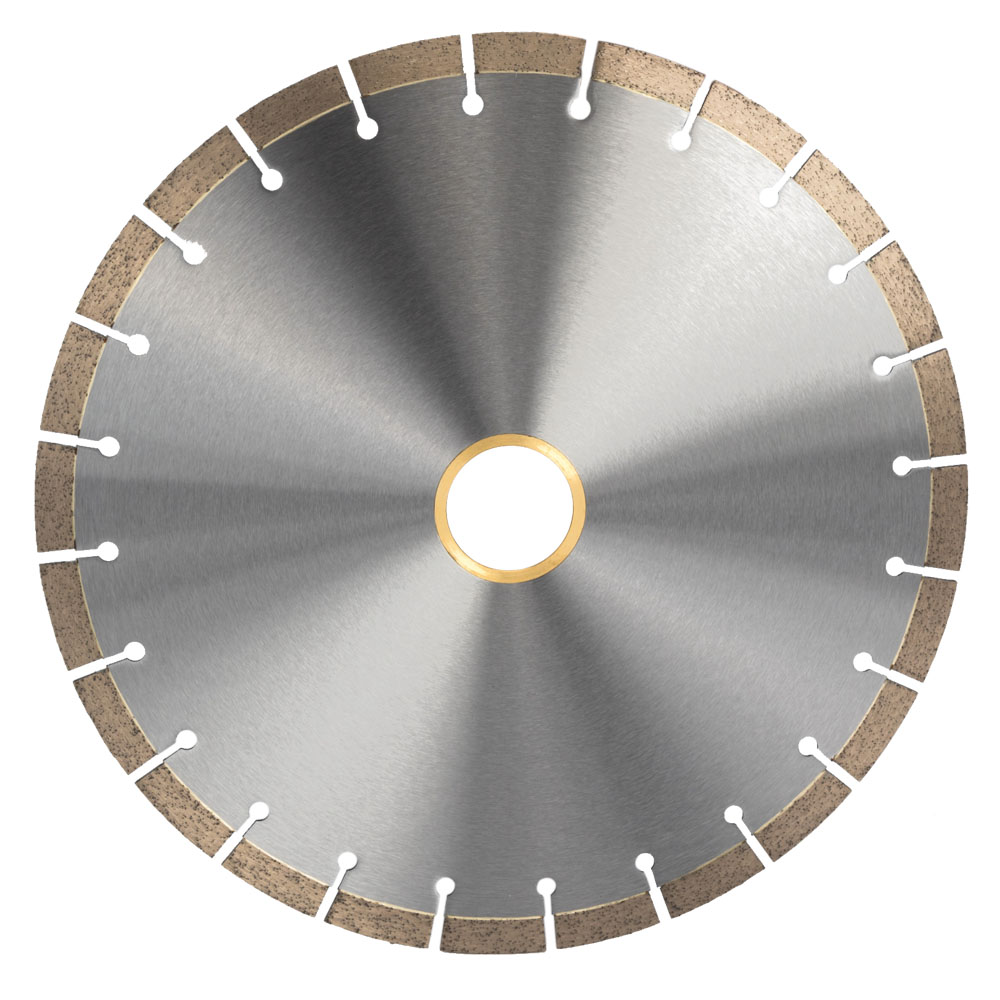

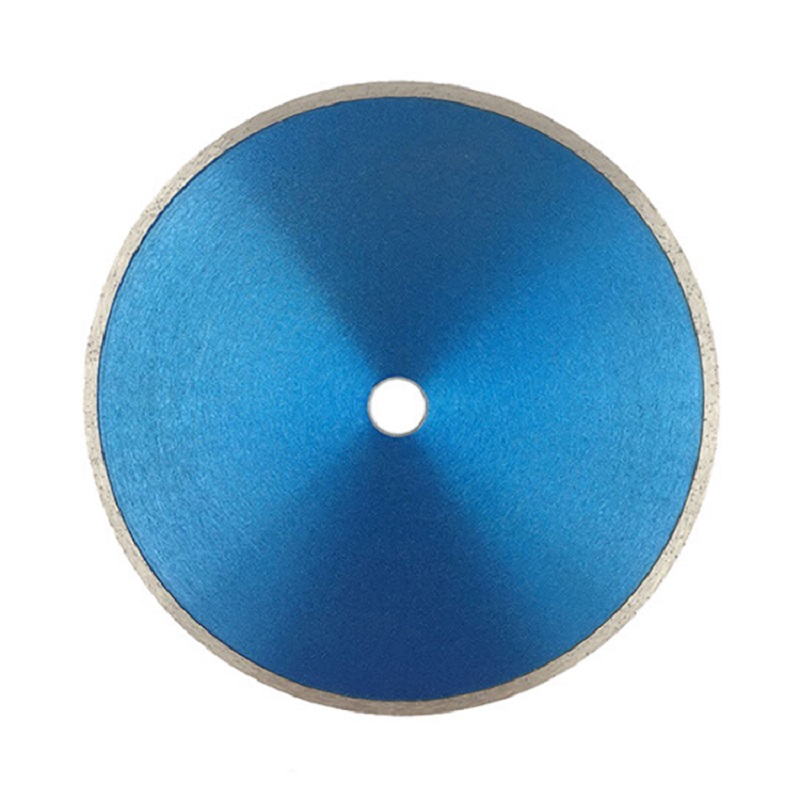

Isetyhula yeSintered Diamond yabona iBlade yokusika i-asphalt

iingenelo

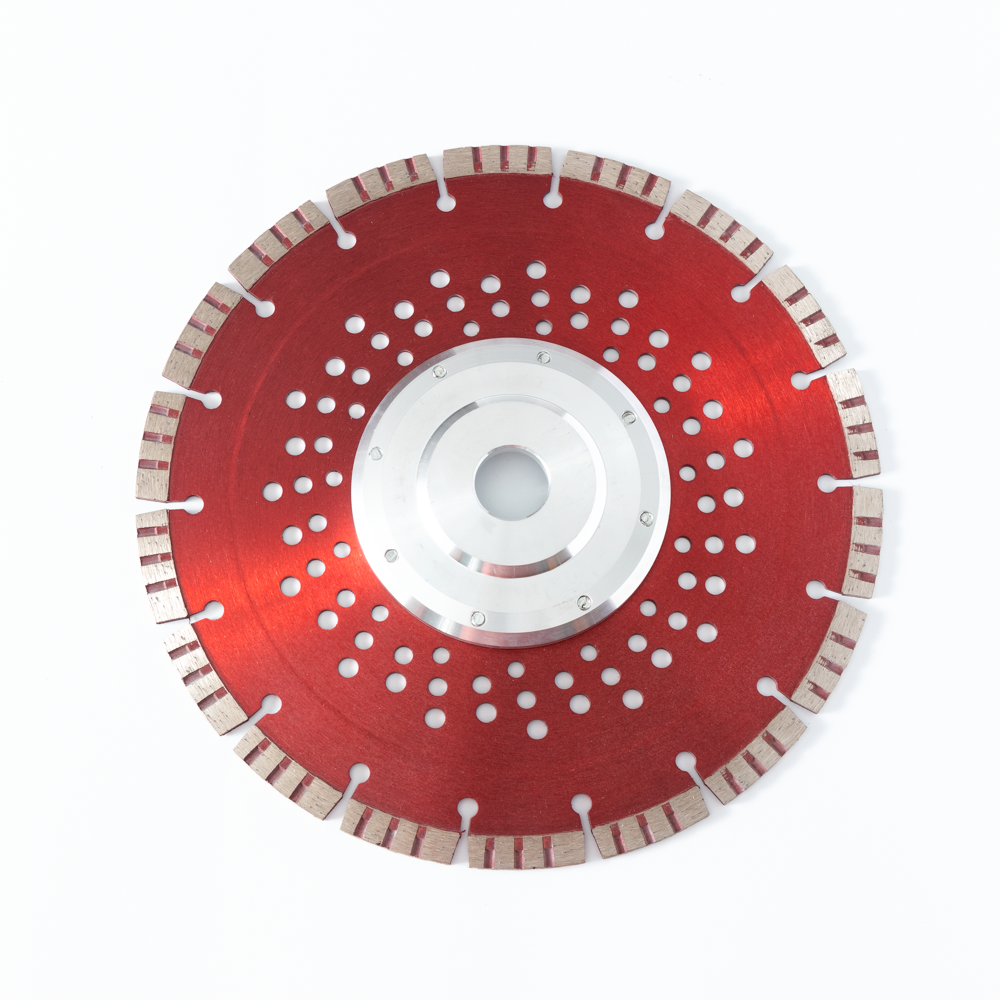

I-1.Sintered diamond saw blades ziyaziwa ngokuhlala kwazo okungaqhelekanga kunye nokuqina, okuzenza zibe zilungele ubume be-abrasive yokusika i-asphalt. Inkqubo ye-sintering yenza ibhondi eyomeleleyo phakathi kwencam yedayimani kunye ne-blade, iqinisekisa ukusebenza okuhlala ixesha elide.

I-2.Sintered diamond saw blades zenzelwe ukusika i-asphalt ngokufanelekileyo, okukhokelela ekusebenzeni ngokukhawuleza, ukusika okugudileyo. Oku kunceda ukwandisa imveliso kunye nokunciphisa iindleko zabasebenzi.

I-3.Uyilo lwe-diamond blades ene-sintered luhlala lubandakanya iimpawu ezikhuthaza ukutshatyalaliswa kobushushu obusebenzayo ngexesha lokusika. Oku kunceda ukukhusela i-blade ekutshiseni, ukunciphisa umngcipheko wokulwa okanye umonakalo, kunye nokwandisa ubomi be-blade.

4.Ngelixa ubukhulu becala isetyenziselwa ukusika i-asphalt, iiblades zedayimani ezisinkiweyo zikwasebenza kakuhle ekusikeni ezinye izinto ezirhabaxa ezifana nekhonkrithi entsha, izitena kunye nobume bamatye, ukubonelela ngeendlela ezahlukeneyo kwiikontraka kunye neengcali zokwakha.

Iingcebiso ze-diamond ezi-5.Sintered zinceda ukunciphisa ukutshiza, ukuqinisekisa ukucoceka okucocekileyo, ukucutha okuchanekileyo okubangelwa umgangatho ophezulu ogqityiweyo kunye neemfuno ezincinci emva kokulungiswa.

I-6.I-diamond blades ene-Sintered ifuna ukugcinwa okuncinci kunye nokutshintshwa kwe-blade frequency kunezinye iintlobo ze-blade, ezinceda ukunciphisa iindleko zokusebenza kunye nexesha lokuphumla.

I-7.Ubomi obude kunye nokusebenza okuphezulu kwe-diamond ye-sintered saw blades kubenza kube yindleko-esebenzayo yokukhetha ukusika i-asphalt, ukubonelela ngebhalansi elungileyo phakathi kotyalo-mali lokuqala kunye nokusebenza kwexesha elide.

Uvavanyo lweMveliso

INDAWO YEFACTORY

| Ububanzi (mm) | Ubude becandelo(mm) | Ububanzi becandelo(mm) | Ubude becandelo(mm) | Inani |

| 200 | 40 | 3.2 | 10 | 14 |

| 250 | 40 | 3.2 | 10 | 17 |

| 300 | 40 | 3.2 | 10 | 21 |

| 350 | 40 | 3.2 | 10 | 24 |

| 400 | 40 | 3.6 | 10 | 28 |

| 450 | 40 | 4.0 | 10 | 32 |

| 500 | 40 | 4.0 | 10 | 36 |

| 550 | 40 | 4.6 | 10 | 40 |

| 600 | 40 | 4.6 | 10 | 42 |

| 700 | 40 | 5.0 | 10 | 52 |

| 750 | 40 | 5.5 | 10 | 56 |

| 800 | 40 | 5.5 | 10 | 46 |