Isikhokelo sokugqibela kwiiBits Core Diamond: Revolutionizing Precision Drilling Technology

Iintlobo kunye noHlelo lweeBits ezingundoqo zeDayimane

Iintlobo kunye noHlelo lweeBits ezingundoqo zeDayimane

Amasuntswana ondoqo wedayimani afika kuhlengahlengiso olwahlukeneyo, ngalinye liyilelwe ukujongana nemingeni ethile yokomba kunye neentlobo zezinto. Ukuqonda olu kuhlelwa kubalulekile ekukhetheni isuntswana esifanelekileyo kuso nasiphi na isicelo esinikiweyo.

Eyomileyo vs

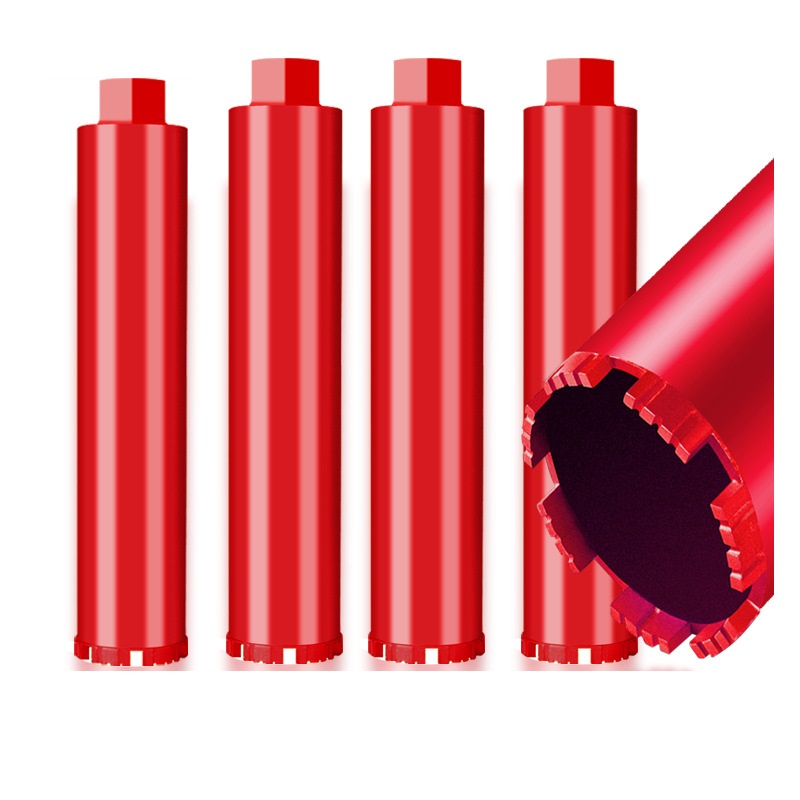

Omnye weyona mahluko uphambili kumbindi wedayimani ulele kwiindlela zokupholisa. Amasuntswana ondoqo wedayimane owomileyo, njengeseti ye-CorePlus CORDCDKIT7, yenzelwe imisebenzi apho ukupholisa kwamanzi kungenzeki okanye kungafunekiyo 1. La masuntswana abonisa i-ribbed core body kunye ne-V-groove segment evumela ukucocwa ngokukhawuleza kobutyobo, evumela isenzo esiqhubekayo sokusika. Uyilo olungundoqo olunomoya luphucula ukupholisa kwaye lwandise ubomi obungundoqo, lubenze balungele iimeko zokomba ongaphezulu okanye apho kusetyenzwa khona imathiriyeli engavani namanzi.

Amasuntswana angundoqo wedayimani emanzi, kwelinye icala, afuna ukupholiswa kwamanzi ngexesha lokusebenza ukuthintela ukufudumeza okugqithisileyo kunye nokwandisa ubomi bentwana. Ezi bits, ezifana ne-25-102mm laser-welded wet diamond core bits, zenzelwe ngokukodwa ukugaya ikhonkrithi eyomeleziweyo kunye nokubonelela ngezakhono zokupholisa eziphezulu ezivumela ukungena okunzulu kunye nokukhawuleza kwizinto ezinzima.

Impregnated vs. Surface-Seti Bits

Olunye ulwahlulo olubalulekileyo lwahlula phakathi kwamasuntswana angundoqo wedayimani omiliselweyo kunye nomphezulu osetiwe. Amasuntswana amiliselweyo abonisa iidayimani ezisasazwa kuyo yonke i-matrix ye-bit, efana ne-61.5mm emiliselwe i-diamond core bit eyenzelwe i-granite hard rock drilling.

Amasuntswana abekwe phezu komhlaba anedayimane eveziweyo kumphezulu we-matrix, ebonelela ngesenzo sokusika esiqatha esilungele izixhobo ezithambileyo. Ezi bits zihlala zibonelela ngesantya sokuqala esikhawulezayo sokusika kodwa zinokunxiba ngokukhawuleza kunoyilo olufakwe kwi-abrasive applications.

Iintlobo ngeentlobo zoyilo olukhethekileyo

Uyilo olukhethekileyo lwedayimani olungundoqo luye lwavela ukulungisa imingeni ethile yokomba:

- Amasuntswana ePDC (Polycrystalline Diamond Compact): La masuntswana, aquka abasiki bedayimani enziweyo, asetyenziswa kakhulu kuphononongo lwe-oyile nerhasi kunye nesampulu engundoqo yejoloji 3. Zinika ukuqina okubalaseleyo kunye nokusebenza kakuhle kokusika kuzo zombini iifomati ezithambileyo neziphakathi-nzima.

- Amasuntswana ento yedayimani yeConcave: Uyilo oluyilayo olunje ngeStrataBlade bits zonyusa izisiki zejiyometri ezizodwa ezineempawu zeconcave ezahlukileyo ezicutha i-angle yokusika umva werake esebenzayo, evumela ukusika nzulu kwilitye elirhabaxa kunye nefuthe-empembelelo.

- Amasuntswana angqale kwithayile: Amasuntswana ondoqo wedayimane akhethekileyo njengeWürth Diamond tile dry core bit isitulo se-M14 zenzelwe ngokukodwa ukugrunjwa ngokusebenzisa imathiriyeli yeceramic eqine kakhulu ngaphandle kokupholisa kwamanzi.

IiNgcaciso zobuGcisa kunye neMiba yoYilo

Amasuntswana angundoqo wedayimani abandakanya ubunjineli obuntsonkothileyo kunye nemigangatho yokwenziwa echanekileyo yokuqinisekisa ukusebenza okugqibeleleyo kuzo zonke izicelo. Ukuqonda iinkcukacha zabo zobugcisa kubalulekile kukhetho olufanelekileyo kunye nokusetyenziswa.

Umgangatho weDayimane kunye nokuGxininiswa

Ukusebenza kondoqo wedayimani kuxhomekeke ubukhulu becala kumgangatho kunye nokuxinana kweedayimani ezisetyenziswa ekwakhiweni kwayo. Iidayimani zodidi lweshishini zikhethwe ngononophelo ngokusekelwe kubungakanani, imilo, kunye neempawu zamandla ukuze zihambelane neemfuno ezithile zokomba. Ngokomgangatho we-DZ/T 0277-2015 wokomba wedayimani ongundoqo wejoloji, abavelisi kufuneka balandele izikhokelo ezingqongqo malunga nomgangatho wedayimani kunye nokuhanjiswa kwazo ukuqinisekisa ukusebenza okufanayo.

Ukuqulunqwa kweMatrix

I-matrix, okanye i-alloy yentsimbi ebambe iidayimani endaweni, idlala indima ebalulekileyo ekumiseleni iimpawu zokusebenza kwesuntswana. I-matrix kufuneka yenziwe ngobunjineli ukuba inxibe ngesantya esilawulwayo esisoloko sibhentsisa iidayimani ezintsha ngelixa sigcina isidima solwakhiwo. Iindlela ezahlukeneyo zematrix ziyilelwe iintlobo ezithile zokwakheka:

- Iimatriki zokwakheka okuthambileyo: Izixhobo zebhondi ezithambileyo ezinxiba ngokukhawuleza, ziqinisekisa ukuvezwa kwedayimani rhoqo kulwakhiwo olungarhawuzeli kangako.

- Iimatriki zokwakheka okuqinileyo: Iibhondi eziqinileyo, ezikwaziyo ukunxiba ezikhusela ukugcinwa kwedayimani kwindawo ezirhabaxa.

- Iimatriki zokwakheka okuphakathi: Imixube elungelelanisiweyo ebonelela ngokusebenza okugqwesileyo kwimixube.

Uyilo lweBit kunye neJometri

Uyilo lomzimba lwedayimani engundoqo iibhithi zinefuthe kakhulu ekusebenzeni kwazo:

Itheyibhile: Iimpawu zeDiamond Core Bit Design kunye neMisebenzi yazo

| Uyilo loyilo | Umsebenzi | Imizekelo yosetyenziso |

|---|---|---|

| Imijelo yamanzi | Vumela ukupholisa kwamanzi kumphezulu wokusika | Zonke izicelo zokomba ezimanzi |

| Ubude beCandelo | Imisela ubomi kancinci kunye nokumelana nokunxiba | Iiprojekthi zokomba ezinde |

| Ipateni yeCandelo | Ichaphazela isantya sokusika kunye nokususwa kobutyobo | Umsebenzi wokwakha okhawulezayo |

| Uhlobo lomsonto | Uqinisekisa ukuhambelana nezixhobo zokomba | Ukucwangcisa ukomba okusemgangathweni |

| Ububanzi beCandelo | Uphembelela uzinzo kunye nokusika ubundlobongela | Iimfuno zokomba ezichanekileyo |

Uthotho lwe-Husqvarna VARI-DRILL D25 DRY DRY lubonisa indlela iimpawu zoyilo eziphucukileyo eziphucula ngayo ukusebenza, ngolungelelwaniso lwecandelo elithile (3-4mm ubukhulu, 9mm ukuphakama) elungiselelwe iintlobo ezahlukeneyo zekhonkrithi.

Iinkcukacha zobungakanani

Amasuntswana angundoqo wedayimani ayafumaneka kuluhlu olubanzi lobungakanani ukulungiselela iimfuno ezahlukeneyo zokomba. Ubukhulu obuqhelekileyo busuka kwi-bits ye-diameter encinci (encinci njenge-1 intshi / 25mm yomsebenzi ochanekileyo) 4 ukuya kwi-bits enkulu yedayamitha edlula i-200mm kwiiprojekthi ezinkulu zokwakha 7. Umgangatho we-DZ/T 0277-2015 uxela ukunyamezela okuchanekileyo kwe-dimensional ye-geological drilling bits, ukuqinisekisa ukufaneleka okufanelekileyo kunye nokusebenza kwizicelo zobungcali.

Izinto eziluncedo kunye neeNzuzo zeDiamond Core Bits

Ubungangamsha bamasuntswana angundoqo wedayimani ngaphezu kobugcisa obuqhelekileyo bokomba bubonakala kwiinkalo ezininzi zokusebenza kokomba, kubonelela ngeenzuzo ezibonakalayo kwiingcali kuwo wonke amashishini.

Ukusebenza ngokuKhethekileyo kokusika kunye nesantya

Amasuntswana ondoqo wedayimani anika amaxabiso okungena akhawulezayo ngokugqithisileyo xa kuthelekiswa namasuntswana okomba aqhelekileyo, ngakumbi kwimathiriyeli eqinileyo kunye nerhasi. I-StrataBlade concave diamond element bits, umzekelo, ibonise ukuya kuthi ga kwi-28% yokunyuka kwezinga lokungena (ROP) xa kuthelekiswa namasuntswana aqhelekileyo kuvavanyo lwasendle oluqhutywe eHaynesville Basin 10. Oku kusasebenza okuphuculweyo kuguqulela ngokuthe ngqo kwixesha elincitshisiweyo lokomba kunye neendleko eziphantsi zomsebenzi ngeprojekthi nganye.

Ukuchaneka kunye noMgangatho weSika

Isenzo esikhethekileyo sokusika i-diamond core bits ivelisa imingxuma ecocekileyo, echanekileyo kunye ne-chipping encinci okanye umonakalo wezinto eziphathekayo. Oku kuchaneka kubaluleke kakhulu kwiinkqubo apho ijometri yomngxuma echanekileyo kunye neendonga ezisecaleni ezigudileyo ziyimfuneko, njengakwimibhobho yamanzi, umbane, kunye nofakelo lwe-HVAC kwiiprojekthi zokwakha. Amasuntswana akhethekileyo njenge Würth Diamond ithayile eyomileyo engundoqo bit zenzelwe ngokukodwa ukunqanda umonakalo kwimathiriyeli eethe-ethe njengeethayile zeceramic ngelixa zihambisa imingxuma ecocekileyo .

Ubomi obude kunye nokuSebenza kweNdleko

Ngaphandle kweendleko zabo zokuqala eziphezulu, iibhithi zedayimani ezingundoqo zibonelela ngexabiso elikhethekileyo lexesha elide ngobomi obandisiweyo benkonzo kunye nokunciphisa ukuphindaphindeka kokutshintshwa. Amasuntswana ondoqo wedayimani omiliselweyo eveliswe ziinkampani ezifana neHunan Diyfia ziyilelwe ukuba ziveze ngokuqhubekayo iidayimani ezitsha njengoko i-matrix inxiba, ukugcina ukugawula ukusebenza kakuhle kuyo yonke impilo ye-bit 6. Oku komelela kubenza bangabizi kakhulu kwimisebenzi yokomba emikhulu apho utshintsho oluqhelekileyo luya kuba nefuthe elibonakalayo kwimveliso.

Ukuguquguquka kuzo zonke izixhobo

Amasuntswana angundoqo wedayimani abonisa ukuguquguquka okumangalisayo, okukwaziyo ukugrumba kuluhlu olubanzi lwezixhobo ezibandakanya:

- Ikhonkrithi ebambekayo kunye neyomeleziweyo: Ukusetyenziswa okusemgangathweni kulwakhiwo

- Ilitye lendalo kunye nobume bamatye: Kubandakanya igranite, ibhastile, kunye nelitye lekalika

- Iithayile zeCeramic kunye ne-porcelain: Iibhithi ezomileyo ezikhethekileyo zithintela ukuqhekeka

- I-asphalt kunye nezixhobo ezidibeneyo: Ngoyilo oluthile lwe-bit

- Ulwakhiwo lweJoloji: Kwisampulu engundoqo kuphononongo

Ukunciphisa Ukukhathala komsebenzisi

Isenzo sokusika esisebenzayo se-diamond core bits kufuna uxinzelelo olungaphantsi olusezantsi kwaye luvelisa ukungcangcazela okuncinci xa kuthelekiswa neendlela eziqhelekileyo zokomba. Oku kuncipha koxinzelelo lomzimba kuguqulela ekudinweni okucuthekileyo kwabaqhubi, okubaluleke ngakumbi ngexesha lemisebenzi yokugrumba eyandisiweyo okanye xa usebenza ngaphezulu. I-ergonomics ephuculweyo inegalelo kwimveliso ephezulu kunye nokhuseleko oluphuculweyo lwendawo yomsebenzi.

Usetyenziso kunye nokuSetyenziswa kweeBits Core Diamond

Amasuntswana ondoqo wedayimani asebenza imisebenzi ebalulekileyo kuwo wonke amashishini ahlukeneyo, ngalinye lineemfuno ezithile eziphakamisa isakhono esisodwa sezi zixhobo eziphambili.

Ishishini loKwakha kunye neloKwakha

Kwicandelo lolwakhiwo, amasuntswana angundoqo wedayimani ayimfuneko ekudaleni ukuvuleka okuchanekileyo kwezinto eziluncedo, iinkqubo ze-HVAC, imibhobho yamanzi kunye nemibhobho yombane. Ukukwazi kwabo ukunqumla ikhonkrithi eyomeleziweyo ngaphandle kokonakalisa imfezeko yesakhiwo semathiriyeli ejikelezileyo kubenza baxabiseke ngakumbi kuhlaziyo kunye neeprojekthi zokubuyisela. I-25-102mm laser-welded wet diamond core bits ngumzekelo wezixhobo ezikhethekileyo eziphuhliswe kwezi zicelo, ezibonelela ngokugrumba okuhamba ngesantya esiphezulu kunye neziphumo ezicocekileyo kwikhonkrithi kunye nekhonkrithi eyomeleziweyo.

Ishishini leoli negesi

Icandelo lepetroleum lixhomekeke kakhulu kubuchwephesha besuntswana ledayimane eliphambili ekuphononongeni kunye nokombiwa kwemveliso. Amasuntswana e-PDC aye axhaphaka kakhulu kwizicelo ze-oyile ngenxa yokuqina kwazo okuphezulu kunye nokusebenza kakuhle kokomba xa kuthelekiswa namasuntswana e-roller cone esintu. Izinto ezintsha ezisandula ukwenziwa njenge-strataBlade concave diamond element bits zibonise ukuphucuka okubalulekileyo ekusebenzeni kokomba, kunye novavanyo lwasendle kuzo zonke izitya ezinkulu ze-shale ezibonisa ukuphuculwa okungaguqukiyo kweROP.

Izicelo ezizodwa

Ngaphaya kwala mashishini amakhulu, iibhithi zedayimani ezingundoqo zisebenza imisebenzi emininzi ekhethekileyo:

- Ukuveliswa kweSemiconductor: Uphuhliso lwe-100mm ye-crystal yafers yedayimani enye imele impumelelo enokuthi iguqule ulawulo lwe-thermal kwi-electronics yamandla aphezulu 9. Nangona ingeyosicelo sokomba ngokwesibini, olu lutsha lubonisa amandla okwanda kweteknoloji yedayimani.

- Ithayile kunye nomsebenzi wobume bamatye: Amasuntswana angundoqo wedayimani akhethekileyo njengothotho lwe-Würth M14 lwenza iingcali zenze imingxunya egqibeleleyo kwizinto ezicekethekileyo ze-ceramic ngaphandle kokupholisa kwamanzi, ukuthintela umonakalo kwindawo egqityiweyo.

- Uphuhliso lweziseko ezingundoqo: Iziseko zedayimani ezinobubanzi obukhulu zibalulekile ekudaleni ukuvuleka kwezinto eziluncedo, iinkqubo zokuhambisa amanzi, kunye neendawo zokungena kwiiprojekthi zeziseko ezingundoqo.

Izikhokelo zokuKhetha kunye neeNgcebiso zokuSebenza

Ukukhetha isiseko sedayimani esifanelekileyo kwisicelo esithile kufuna ukuqwalaselwa ngononophelo kwizinto ezininzi zokuqinisekisa ukusebenza kakuhle kunye nokusebenza kakuhle kweendleko.

UVavanyo lokuhambelana kwezinto

Inyathelo lokuqala ekukhetheni undoqo wesuntswana ledayimani libandakanya ukuchonga imathiriyeli ephambili ekufuneka yombiwe. Izixhobo ezahlukeneyo zifuna uyilo oluthile lwe-bit kunye noqwalaselo lwedayimane:

- Ikhonkrithi ethambileyo kunye nezitena: Iisuntswana ezisemgangathweni ezisetiweyo zomphezulu kunye nokuvezwa kwedayimani ndlongondlongo

- Ikhonkrithi eyomeleziweyo: Iibhithi eziqinileyo ezinokumelana nobushushu ukwenzela ukuqinisa intsimbi

- Ilitye lentlabathi elonakalisayo: Amasuntswana amiliselweyo anokwakheka kwematrix eyomeleleyo

- I-Ceramic kunye ne-porcelain: I-Fine-grit diamond particles kunye noyilo olukhethekileyo lwecandelo

Ukuhlola ukuhambelana kweZixhobo

Ukuqinisekisa ukuhambelana phakathi kwe-diamond core bit kunye nesixhobo sokomba kubalulekile kukhuseleko kunye nokusebenza. Iingqwalasela eziphambili ziquka:

- Ukuhambelana kohlobo lomsonto: Udibaniso olusemgangathweni lubandakanya 1/2″ BSP, M14, M16, kunye no-5/8″-11 umsonto we-18.

- Iimfuno zamandla ezixhobo: Ukuqinisekisa itorque eyaneleyo kunye nezakhono zeRPM

- Ukuhambelana kwenkqubo yokupholisa: Ukudibanisa iibhithi ezimanzi / ezomileyo kunye nezixhobo ezifanelekileyo

IiNdlela zokuSebenza eziNgcono

Ukusebenza okufanelekileyo kwandisa kakhulu ubomi kwaye kuqinisekisa ukusebenza okufanelekileyo:

- Ukupholisa okwaneleyo: Ukugcina ukuhamba kwamanzi ngendlela eyiyo kumasuntswana amanzi okanye izithuba ezifanelekileyo zokomba kwiibhithi ezomileyo.

- Uxinzelelo olufanelekileyo: Ukufaka uxinzelelo olwaneleyo lokusika ngokufanelekileyo ngaphandle kwamandla agqithisileyo abangela ukushisa okugqithisileyo

- Ukucoca rhoqo: Ukucoca i-debris kwimingxuma kunye ne-bit segment ukuthintela ukuvaleka

- Uhlengahlengiso lwesantya: Ukuguqula i-RPM ngokusekwe kubulukhuni bezinto kunye nobubanzi bebit

ULondolozo kunye noGcino

Ulondolozo olufanelekileyo lwandisa ubomi besuntswana ledayimani kwaye lugcina ukusebenza kokusika:

- Ukucoca ngokucokisekileyo emva kokusetyenziswa ngakunye ukususa inkunkuma kumacandelo

- Ukugcinwa ngokufanelekileyo kwiimeko zokukhusela ukukhusela umonakalo wedayimane

- Ukuhlolwa rhoqo kwecandelo lokunxiba okanye umonakalo ngaphambi kokusetyenziswa ngakunye

- Iinkqubo zokulola amasuntswana amiliselweyo xa umsebenzi wokusika uyancipha

Izinto ezintsha kunye neendlela ezizayo kwiTekhnoloji yeDiamond Core Bit

Ishishini lesuntswana ledayimani elingundoqo liyaqhubeka nokuvela, kunye nophando oluqhubekayo kunye nophuhliso olugxile ekuphuculeni ukusebenza, ukwandisa izicelo, kunye nokunciphisa iindleko.

IiMathiriyeli eziPhezulu kunye nokuVeliswa

Inkqubela phambili yamva nje kwisayensi yezinto ikhokelele kuphuculo olubonakalayo kwitekhnoloji yebit engundoqo yedayimani. Ukuphuhliswa kweedayimani zokwenziwa ze-premium-grade ezineempawu ezilawulwa ngononophelo zenze ukuba abavelisi basebenzise ugxininiso lwedayimani kunye nokusasazwa kwezicelo ezithile. Ukongeza, ukuveliswa kwezinto ezintsha kwisinyithi kunye nedayimane / ubuchule bokudibanisa isinyithi bukhokelele kwimathiriyeli yematrix eyomelele ngakumbi eyandisa ubomi kancinci kulwakhiwo olucelomngeni.

Ijometri ekhethekileyo kunye neHydraulics

Abavelisi beBit baya bejolisa ngakumbi kuyilo lwehydraulic oluphuculweyo oluphucula ukupholisa kunye nokususwa kobutyobo, okuphucula ukusebenza kokugrumba kunye nobomi kancinci. I-strataBlade concave diamond element bits with their unique geometry imele lo mkhwa, ebonisa uyilo lweconcave olwahlukileyo olunciphisa i-angle esebenzayo yokusika umva wokungena nzulu.

Ukudityaniswa neDigital Technologies

Ikamva le-diamond core bit technology ibandakanya ukudityaniswa okukhulu kunye neenkqubo zedijithali zokubekwa kweliso nolawulo oluchanekileyo. Iinkqubo zokugrumba ezihlakaniphile ezilungelelanisa iiparamitha ngexesha lokwenyani ngokusekelwe kwingxelo yokuqulunqa ziya zixhaphaka ngakumbi, ngakumbi kwizicelo zeoyile negesi. Ezi nkqubo ziphucula ukusebenza kancinci kwaye zithintele umonakalo ngokuziqhelanisa nokutshintsha kweempawu zokwakheka ngexesha lemisebenzi yokomba.

Iingqwalasela zokusiNgqongileyo kunye noKucikideka

Ugxininiso olukhulayo ekuzinzeni luqhuba ukuveliswa kwezinto ezintsha kubuchwephesha bokwemba amandla. Iibhithi ezingundoqo zedayimani zinegalelo kwezi njongo ngokunciphisa ixesha lokomba kunye nokusetyenziswa kwamandla aphantsi xa kuthelekiswa neendlela eziqhelekileyo. Ukongeza, uphuhliso lweenkqubo zokomba ezomileyo eziphelisa ukusetyenziswa kwamanzi zijongana neenkxalabo zokusingqongileyo kwiindawo ezingevani namanzi ngelixa kugcinwa ukusebenza kakuhle kokomba.

Isiphelo: Ikamva Lokugrumba ngeeBits ezingundoqo zeDayimane

Iziseko zedayimani ezingundoqo zizimise njengezixhobo eziyimfuneko kuwo onke amashishini amaninzi, zibonelela ngokusebenza okungenakuthelekiswa nanto ekwembeni ngokusebenzisa izixhobo ezinzima. Ukusuka kulwakhiwo kunye nokumbiwa kwemigodi ukuya kwizicelo ezikhethekileyo kwimveliso ye-semiconductor, ezi zixhobo zokusika eziphucukileyo ziyaqhubeka nokuvela ngokuqhubeka nokuveliswa kwezinto ezintsha, uyilo kunye neenkqubo zokuvelisa.

Ikamva letekhnoloji yedayimani engundoqo ithembisa ukusebenza kakuhle ngakumbi, ukuchaneka, kunye nokuguquguquka njengoko abavelisi bebandakanya ulwazi oluvela kwisayensi yezinto, itekhnoloji yedijithali, kunye nobunjineli obuphambili. Uphuhliso oluqhubekayo lwamasuntswana akhethekileyo kwizicelo ezithile, kunye nokuphuculwa komgangatho wedayimani kunye nokwenziwa kwematriki, kuya kwandisa ngakumbi amandla ezi zixhobo ziphawulekayo.

Njengoko uphuhliso lweziseko zophuhliso lwehlabathi luqhubeka kwaye nokuphononongwa kwemithombo yobutyebi kungena kwiindawo ezicela umngeni ngakumbi, ukubaluleka kobuchwephesha besuntswana ledayimani kuya kwanda kuphela. Amagcisa kuwo onke amashishini anokulindela ukubona inkqubela phambili ephucula ukusebenza kakuhle kokomba, ukunciphisa iindleko zokusebenza, nokwenza usetyenziso olutsha olungaphaya kwamandla ethu obugcisa.

Nokuba kudala imivulo echanekileyo kwikhonkrithi eyomeleziweyo, ukufumana iisampulu ezingundoqo kunzulu ngaphantsi komhlaba, okanye ukwenza impumelelo kulawulo lobushushu be-elektroniki, amasuntswana angundoqo wedayimani aya kuqhubeka ukudlala indima ebalulekileyo ekubumbeni okusingqongileyo nokwandisa ukuqonda kwethu indalo.

Ixesha lokuposa: Aug-31-2025