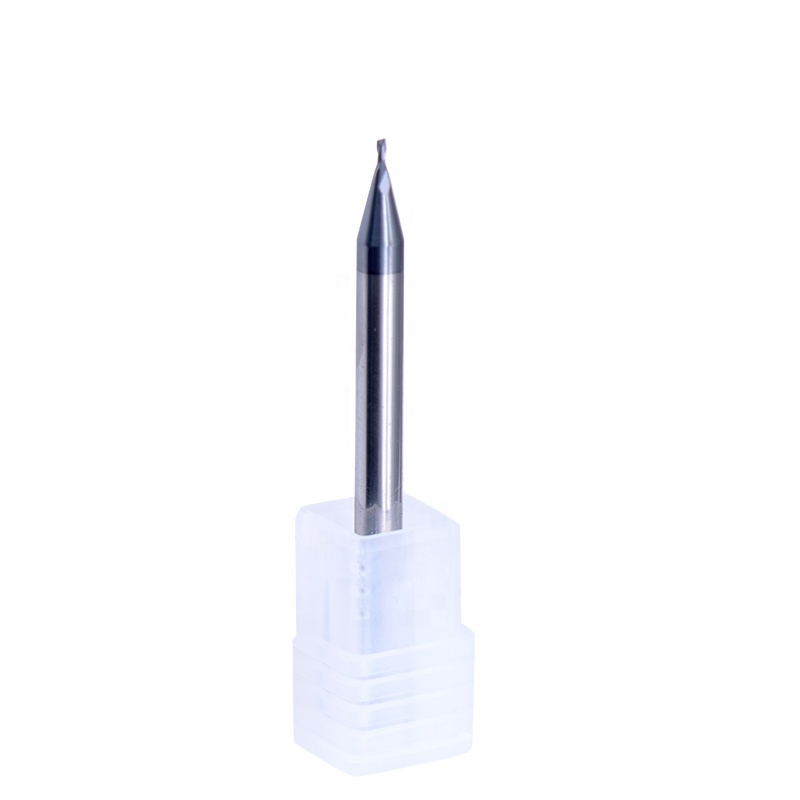

Micro Tungsten Carbide Square End Mill

Iimbonakalo

1. Idayamitha encinci: Izixhobo zokusila ezincinci zihlala zinedayamitha ukusuka kwi-0.1mm ukuya kwi-6mm, zivumela ukusikwa okuchanekileyo kunye nokuntsonkothileyo kwiindawo ezixineneyo. Oku kuvumela ukwenziwa kweenkcukacha ezintle kunye neempawu ezincinci ngokuchaneka okuphezulu.

2. Ubunzima obuphezulu: I-tungsten carbide iyaziwa ngobunzima bayo obugqwesileyo, obuqinisekisa ukuqina kwe-micro end mill kunye nokuchasana nokunxiba. Oku kubenza bafaneleke ukwenza izinto eziqinileyo ezifana nentsimbi engatyiwa, iintsimbi zesixhobo esomeleleyo, kunye nealloys ye-aerospace.

3. Imiphetho ebukhali yokusika: Iincinci zeMicro end ziyilelwe ngamacangca abukhali ukuze kuqinisekiswe ukusikwa okucocekileyo kunye nokunciphisa umngcipheko womonakalo we-workpiece okanye i-burrs. Oku kubalulekile kwizicelo ezifuna ukugqitywa komphezulu ophezulu kunye nokuchaneka komphezulu.

4. Ukukhutshwa kwetshiphu okusebenzayo: Uyilo lwefleyiti lwe-micro end Mills lulungiselelwe ukukhutshwa okusebenzayo kwe-chip, ukuthintela ukwakhiwa kwe-chip kunye nokuqinisekisa ukusebenza kakuhle kokusika. Ukukhutshwa kwe-chip ngokufanelekileyo kunceda ukugcina ukusebenza kakuhle kwesixhobo kunye nokunciphisa ithuba lokuphuka kwesixhobo.

5. Ukunciphisa amandla okusika: I-Micro end Mills yenzelwe ukunciphisa amandla okusika, okubaluleke kakhulu xa usebenza ngezinto ezinqabileyo okanye ezincinci. Amandla okusika asezantsi anceda ukuthintela ukuphambuka komsebenzi kunye nokunciphisa ithuba lokunxiba isixhobo okanye ukwaphuka.

6. Izinketho zokugubungela: I-Micro tungsten carbide end mills inokufumaneka ngeengubo ezahlukeneyo, ezifana ne-TiAlN, i-TiSiN, okanye i-diamond-like carbon (DLC). Ii-coatings zandisa ukusebenza kwesixhobo ngokunciphisa ukukhuhlana, ukuphucula ukuxhathisa ukunxiba, kunye nokuphucula ukuchithwa kobushushu.

7. Ukhetho lwefluti ezininzi: Ii-Micro end Mills zinokuba ne-2, 3, okanye ne-4 flute. Inani leefluti lichaphazela ukukhutshwa kwe-chip kunye nokuzinza kwesixhobo ngexesha lokusika. Ukukhetha uyilo olufanelekileyo lwefluti kuxhomekeke kwisicelo esithile kunye nezinto ezenziwa ngoomatshini.

8. Izinketho ze-Shank: Ii-Micro end Mills zinokubonelelwa ngeentlobo ezahlukeneyo ze-shank, kubandakanywa i-shank straight and tapered shanks. Ukukhethwa kohlobo lwe-shank kuxhomekeke kumphathi wesixhobo somatshini kunye neemfuno ezithile zokucwangciswa komatshini.

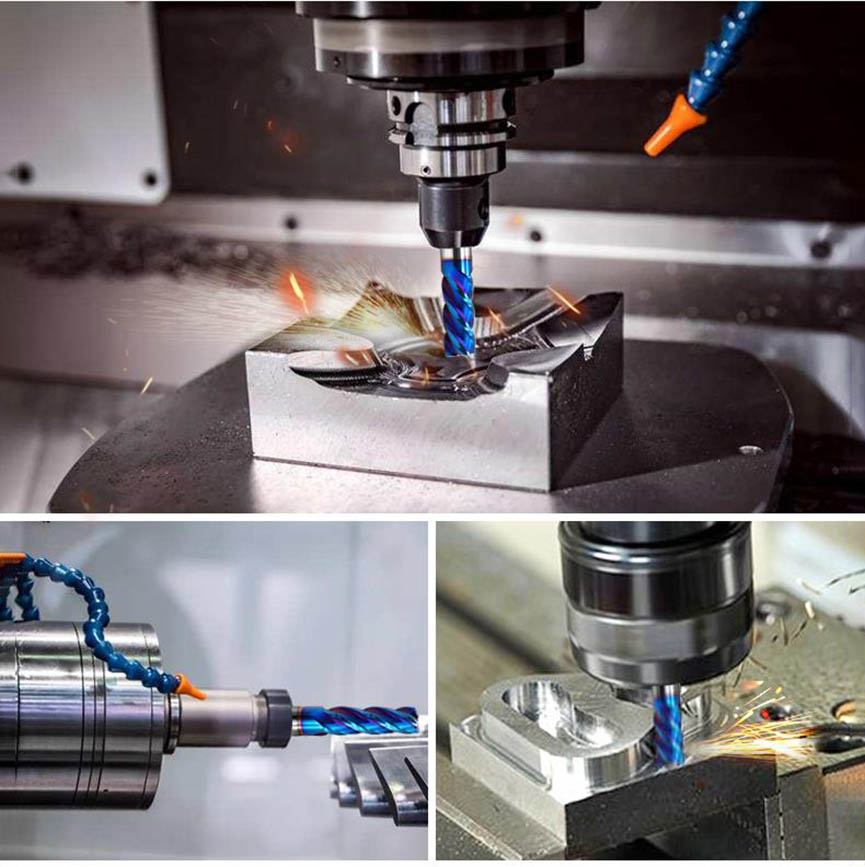

9. Ukuguquguquka kwesicelo: I-Micro tungsten carbide end Mills ifanelekile kuluhlu olubanzi lwezicelo, kubandakanywa i-micro machining, i-engraving, i-contouring, kunye ne-drilling. Zingasetyenziswa kumashishini afana ne-electronics, amayeza, i-aerospace, kunye nobunjineli obuchanekileyo.

10. Iinketho zokwenza ngokwezifiso: Abavelisi bahlala benikezela ngeenkonzo zokwenza ngokwezifiso kwii-micro end mill, evumela abathengi ukuba bachaze ububanzi, ubude beflute, ubude obupheleleyo, i-coating, kunye nezinye iiparameters ukuhlangabezana neemfuno zabo zomatshini.

preminium umgangatho tungsten carbide isikwere ekupheleni ilitye lokusila iinkcukacha

umzi-mveliso

| 2 Flutes Micro End Mill | ||||

| Into | Flute Diameter(d) | Ubude beFlute(I) | IShank Diameter(D) | Ubude bonke(L) |

| 0.2*0.4*4*50 | 0.2 | 0.4 | 4 | 50 |

| 0.3*0.6*4*50 | 0.3 | 0.6 | 4 | 50 |

| 0.4*0.8*4*50 | 0.4 | 0.8 | 4 | 50 |

| 0.5*1*4*50 | 0.5 | 1 | 4 | 50 |

| 0.6*1.2*4*50 | 0.6 | 1.2 | 4 | 50 |

| 0.7*1.4*4*50 | 0.7 | 1.4 | 4 | 50 |

| 0.8*1.6*4*50 | 0.8 | 1.6 | 4 | 50 |

| 0.9*1.8*4*50 | 0.9 | 1.8 | 4 | 50 |