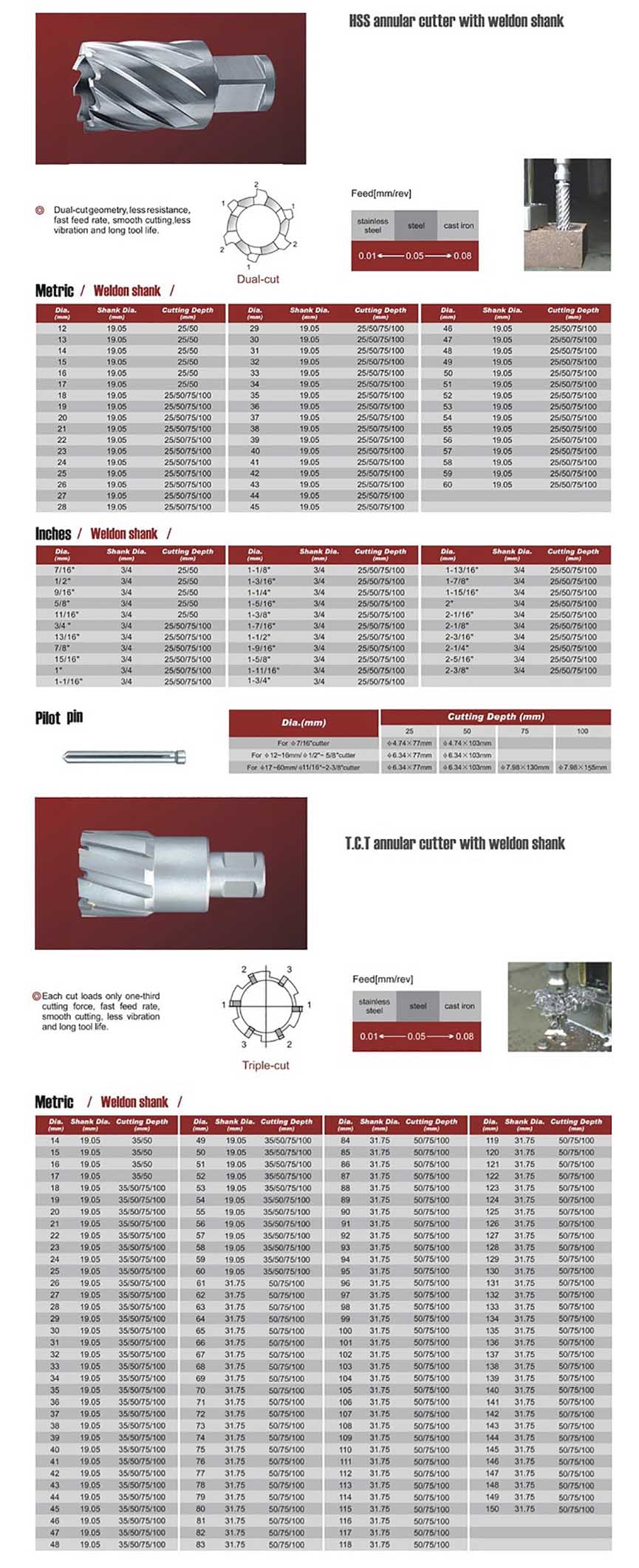

HSS M2 Annular Cutter kunye Weldon Shank

Iimbonakalo

1. Yenziwe kumgangatho ophezulu kunye nentsimbi enesantya esiphezulu esinesantya esiphakamileyo esinejiyometri esisike kaninzi ukusika iplyi kunye nokukhuhlana okusezantsi ukufikelela ngcono.ukunyamezela kunye nokuqhekeka okuncinci.

2. Ifanelekile kwintsimbi (njenge-T-brackets, amaphepha amakhulu), isinyithi esityhidiweyo, i-non-ferrous and light metal.

3. I-geometry ephuculweyo ephuculweyo yokwandisa ukusebenza kokusika kunye nokunciphisa amandla okusika.

4. Ii-angles zokusika ezisebenzayo zenzelwe ukusetyenziswa kwendawo yonke kwiintlobo ezahlukeneyo zetsimbi.

5. Ukususwa okuphuculweyo kweetshiphusi enkosi kwiindawo zokungena ezimilise u-U. Ijometri ethile ye-recess inciphisa umthwalo we-thermal kwi-drill engundoqo ye-HSS njengoko ubushushu obudalwe ekusikeni bususwa kunye neechips ukuya kwinqanaba elikhulu kakhulu.

6. Ukucutha ukukhuhlana phakathi kwe-HSS core drill kunye ne-workpiece ngenxa ye-spiral-shaped guide chamfers.

7. I-Weldon shank ingena kuninzi lwezibhobho zemagnethi.

IDIAGRAM YOKUSEBENZA KWABANDLA

Iingenelo

1. I-Speed-Speed Steel Construction: I-HSS i-annular cutters yenziwe ngetsimbi ye-speed-speed, uhlobo lwensimbi yesixhobo eyaziwa ngokuba lukhuni, ukuqina, kunye nokuchasana nokugqoka nokushisa. Olu lwakhiwo luqinisekisa ukuba i-annular cutter inokumelana nokugaya i-high-speed drilling kwaye igcine ukusebenza kwayo nakwiimeko ezinzima.

2. Ukusika ngokukhawuleza nangokuSebenzayo: Xa kuthelekiswa nemigangatho ye-twist drill yendabuko, i-annular cutters yenzelwe ngokukodwa izicelo zokusika umngxuma. Ijometri yabo ekhethekileyo, kunye namazinyo okanye iifluti kwi-cut cut, ivumela ukususwa kwezinto ngokukhawuleza kunye nokusebenza kakuhle. Esi santya kunye nokusebenza kakuhle kunciphisa ixesha lokomba jikelele, ukwandisa imveliso.

3. Izisiki ezichanekileyo nezichanekileyo: I-HSS annular cutters ivelisa imingxuma ecocekileyo, engena-burr, kunye nobukhulu obuchanekileyo. I-pilot pilot okanye i-centering pin, kunye nemiphetho yokusika eyilwe kakuhle, yenza ukuba indawo echanekileyo ibekwe kunye nokugrunjwa, okukhokelela kwimingxunya egqityiweyo ekumgangatho ophezulu kunye nenkangeleko yobuchwephesha.

4. I-Versatility: I-HSS i-annular cutters ingasetyenziselwa kwizinto ezahlukeneyo ze-ferrous kunye ne-non-ferrous, kubandakanywa intsimbi, insimbi engenasici, i-aluminium, ithusi, ubhedu, kunye nokunye. Oku kuguquguquka kubenza bafanelekele uluhlu olubanzi lwezicelo kumashishini afana nokwakha, ukuvelisa, ukwenza isinyithi, kunye nokwenza.

5. UkuPhuculwa kweChip okuPhuculweyo: Abasiki be-annular banamaziko angenanto, avumela ukukhutshwa okusebenzayo kwe-chip ngexesha lokomba. Olu phawu luthintela ukuvala i-chip kwaye luqinisekisa ukutshatyalaliswa kobushushu obungcono, ukwandisa ubomi besixhobo kunye nokugcina ukusebenza kokusika okungaguqukiyo.

6. Ukuhambelana neMagnetic Drilling Machines: I-HSS annular cutters yenzelwe ukusetyenziswa ngoomatshini bokugaya magnetic. Abasiki banokuthi badityaniswe ngokukhuselekileyo kwisiseko samagnetic somatshini, ukubonelela ngokuzinza, ukuchaneka, kunye nokulula kokusetyenziswa ngexesha lokugaya.